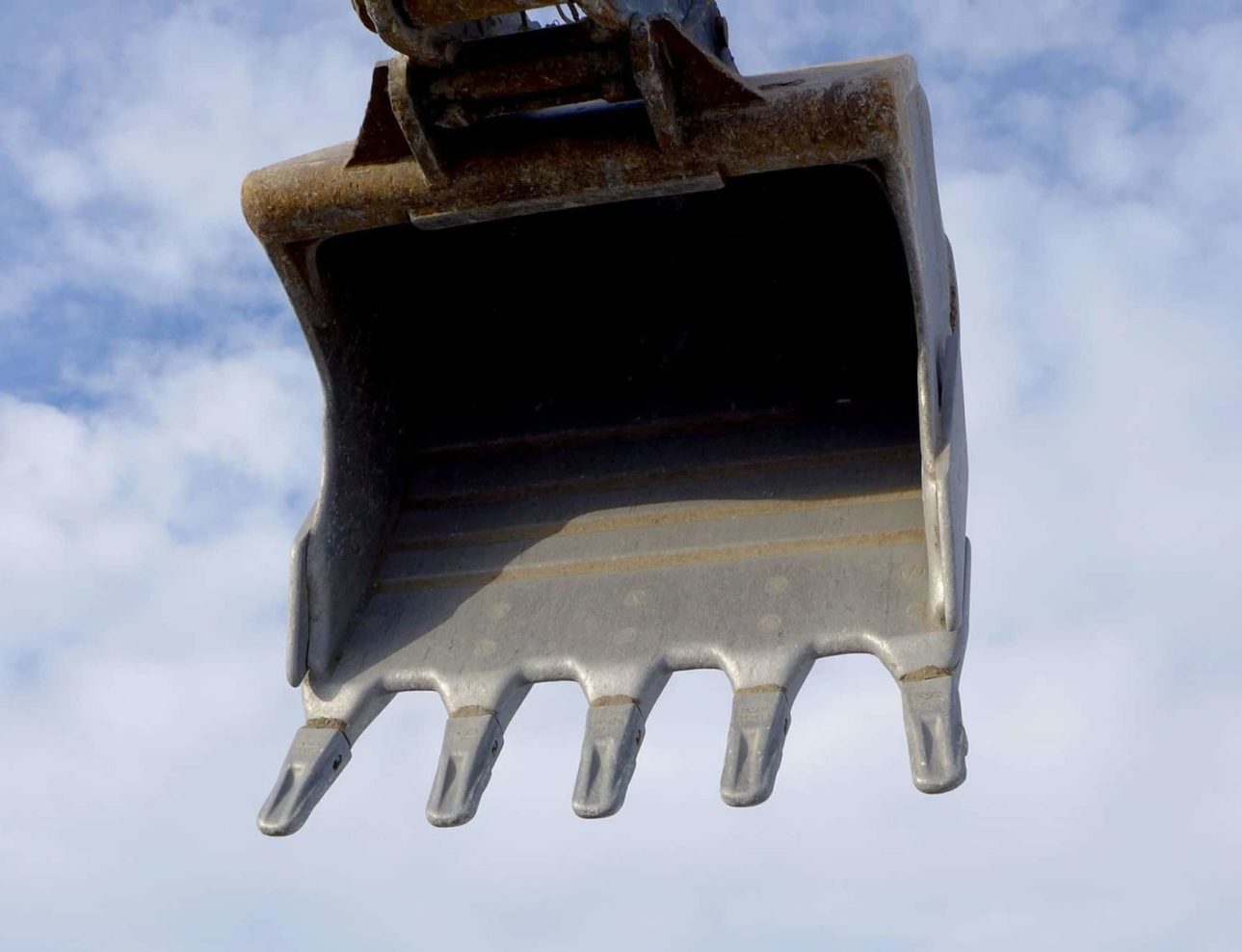

E2® Tooth System

The new replaceable tip tooth system from Norway-based KVX offers the same slim profile as its well-known reversible adapterless tooth system.

As the E2® adapter is affixed on the underside of the lip, the system profile remains lower and slimmer than conventional systems, improving penetration and thereby overall productivity. The adapter is bolted-on with one or two bolts, depending the size of the machine.

For more information, please contact our sales department. If you wish to get a quotation for a KVX GET, please fill out our inquiry form.

E2® has several advantages over conventional cast adapter systems

Replaceable tooth tips

The replaceable tooth tips are designed for optimal lifetime and consumable efficiency.

The uniquely slim profile simply allows us to put more usable wear steel % in the tip. The design offers better penetration, better performance and less strain on the machine.

Same lip = a flexible system

The KVX E2® is essentially built on the same foundation as the renowned classic KVX bolt-on adapterless tooth system.

This means you can change between the classic 1-piece teeth and the new E2® system on the same lip, simply by unbolting one option and bolting on the other. This provides great flexibility as application needs change.

The Pin – easy and “hammerless”

The all-new E2® features arguably the most highly regarded pinning system on the market… the XS hammerless pin developed by Hensley.

As such, tip replacement is performed easily, quickly and safely through the use of conventional socket spanners.

The E2® adapter offers superior lifetime

The adapter is what makes the E2® system so different to conventional adapter system offerings.

While most adapter systems are welded to the bucket lip, and conventional bolted adapters suffer a reputation for poor durability, the E2® adapter utilises the same unsurpassed bolting technology as KVX’s renowned reversible adapterless teeth. The KVX bolting system has proven its very high reliability and durability over more than 30 years, in extreme applications all over the world. See additional advantages below.

More advantages

The KVX adapter is manufactured from the same special steel alloys as KVX’s traditional reversible teeth, with a hardness of 500 Brinell (HBW 10/3000) throughout, and extreme toughness unrivalled by cast steel alternatives.

Our use of specialised bolting technology allows this, as no welding is necessary. The result is an adapter with longer lifetime than conventional cast adapters. The elimination of welding also saves the lip from potential heat-induced cracking over its service life, and further eliminates the down-time associated with welding and welding-related problems.

Utilisation of a ~500 Brinell high toughness adapter also offers further advantages though: The nose of the adapter is better “matched” to the hardness of the replaceable tips, and is significantly more resistant to wear and deformation from the tooth tips and fines contamination between adapter and tips, making the E2® adapter noses much more reliable.

The KVX adapters are bolted to the outside of the bucket, therefore providing significant protection externally to the lip and bucket floor. Meanwhile, the inside of the bucket is left smooth and clean to enhance optimal material flow both in and out of the bucket (easier digging and faster, more effective dumping).

Last but not least; in addition to changing teeth tips quickly and simply, you can also easily change the KVX adapter out in the field with just a simple spanner and spanner stand. No need for welding or the ongoing welding repairs/ logistics commonly experienced with conventional systems. That means more hours in production and minimal maintenance!

As the E2® adapter is affixed on the underside of the lip, the system profile remains lower and slimmer than conventional systems, improving penetration and thereby overall productivity.

For more information, please contact our sales department. If you wish to obtain a quotation for a KVX GET system, please fill out our inquiry form.